I start digging and suddenly I’m doing global Supply-chain analysis.

If you don’t know about Eupa, you should. Your mind will be blown.

Eupa-the world’s largest factory not only provides jobs, but weddings, places to live, fresh restaurant meals, and nearby shops. Romance at work is encouraged and weddings are paid for by the company and take place there. Wages range from $100/month to $300. Rent is typically $6 and meals 50cents.

https://www.youtube.com/watch?v=bzlzlPjseao&sns=tw via @youtube

In China, group and the country is more important than the individual and owning a house or land is difficult or impossible. Mothers make no qualms that they wish their daughters were sons. I have heard this first-hand from over-achieving, MIT-equivalent, cum laude-type friends. Young Chinese women are then propelled to prove their worth by studying hard and earning good jobs at the big factories.

President Trump speaks harshly about trade deficits, and having been to China and Mexico and speaking both languages and getting to know the people, there’s a human element here that I feel deeply alongside my compassion for the American worker and my country.

As a libertarian, I feel the conflict inside me and I am no trade expert.

I doubt that US workers would work and live like EUPA. “Live, Work Play” is an emerging concept I see in the US appealing to more and more of us who don’t want to be stuck in commute traffic, but US companies don’t subsidize a lifestyle or meals (the wages are higher) but so are the meals) We still have to commute to these “City Centers”. American culture is very individualized and Americans would not wear bright yellow shirts and live in a bright yellow apartment with extended family.

Have a look at at least the first 5 minutes of the video.

You’ll be gobsmacked.

This is why the US cannot compete in this kind of manufacturing. It’s not a sweatshop, it’s an all-inclusive way of life.

Now, back to auto parts.

Where do original (OE) and aftermarket car parts come from and do they need lots of hands to be made?

OE parts

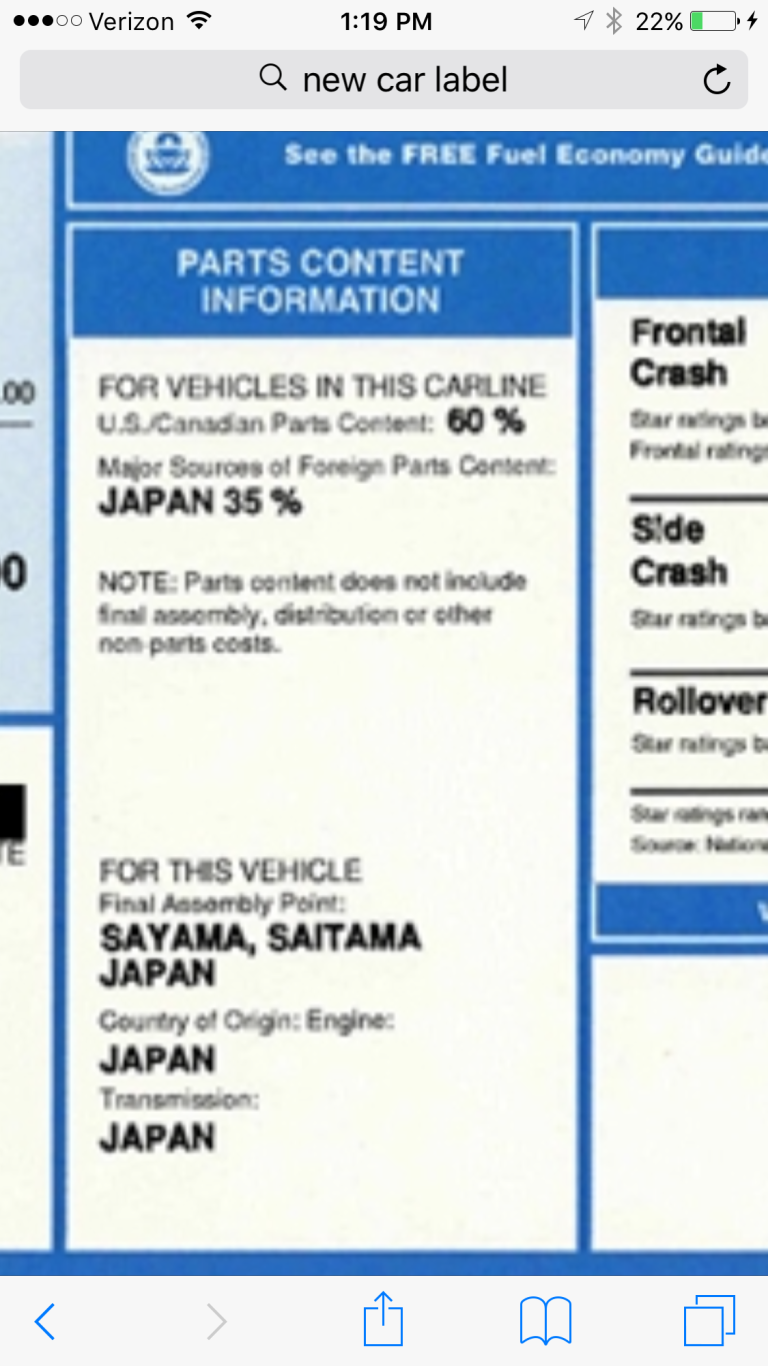

As for original parts, You can look at a car’s sticker to get some idea. Look under the Parts Component box. In this example of a Honda, most of it came from Japan and was assembled there. Because of NAFTA, US=Canada, so you don’t know in which country it’s major components come from, but you usually can tell where it was assembled by robots. My 2009 car came from a plant in Tennessee.

Replacement or aftermarket parts:

I called a few car part places and asked for a big-ticket item like a transmission. They could not order them for me nor did they know where they were made. That will be a follow-up post once those places are open.

Small parts, like oil filters, come from China. “Every part comes from China” one guy said. According to another place with more limited selection, FRAM and STP oil filters are manufactured in the US (I don’t know if that’s really true or if they’re made in Guam or Canada). NAFTA labeling is such that the company can say “made in US” without that meaning the lower 48 states and companies are less than transparent online.

I turned to YouTube and How It’s Made to note the amount of robots and people looking for parts commonly replaced:

*oil filter: robots, 2 workers

*air filter :robots, 3 workers

*alternator: machines, 1 worker

*tires: machines, 3 workers

Given robots, machinery, and the Eupa lifestyle, I just don’t see a lot of manufacturing jobs returning to the US.

Eupa can churn out 50,000 grills and 60,000 irons of 10 brands per day. Each worker can also raise children and have them go to school onsite. Relatives can also live with the workers. All their manufacturing parts and fresh food are also made on site.

So, where will the US manufacturing jobs come from on a massive scale? I don’t know yet, but you can bet I’m watching this administration to see what the real results are.

My guess is that most jobs will be in construction from the big Infrastructure projects proposed. I don’t mind paying a bit more tax for a better airport in Phoenix and helping my fellow American. US airports pale in comparison with Europe and China’s uber modern ones. Those are a site to see, very efficient, clean, and don’t smell bad.

So, part 2b:where do big car parts come from? US? Canada? Mexico?

Stay tuned…

Images and sources from Discovery channel HD, How It’s Made, Autozone, OReilly Auto parts and Pep Boys Autoparts.

After watching ten minutes of the Eupa video, I wonder how such poor supply management is possible when all of the suppliers are a bicycle ride distance. Good thing, each time one of these line managers enters a supplier shop, they don’t have a run-in with a Union steward.

I recall the Japanese small part system as much better organized. The captive family home/factory receives bags and boxes of raw materials from a Honda or Nissan or Toyota delivery truck daily. The truck then takes the parts made yesterday to a sub-assembly factory many miles away. Each family, dad, mom and some children are given a small machine to stamp out brackets and mold plastic pieces that are shipped to a sub-assembly contractor where they are assembled into a door handle and lock system or seat etc. It is a cottage industry that doesn’t require everyone live in the same factory town, although it eventually feeds Toyota city.

Henry Ford was the master of vertical integration in the 1940’s. He owned the mines, rubber plantations, farms, forests and ships delivering the raw materials. The steel mills and foundries, the weaving factories and all feed sub-assemblies at the Ford Rouge plant.

I too await the Trump plan for bring jobs back to America. It will be tough to do, but we also thought that the blight that large cities were experiencing would destroy the heart of big urban areas. Now they are being gentrified and the people locals are protesting the loss of cheap housing.